Improving mine productivity by better analysis of blasting data

Posted Date: 2017-05-26 07:14:10 Posted By: Sushil Bhandari

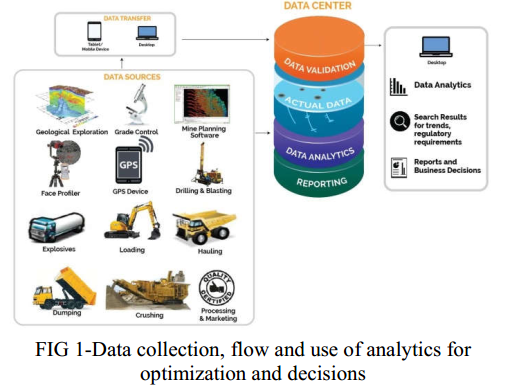

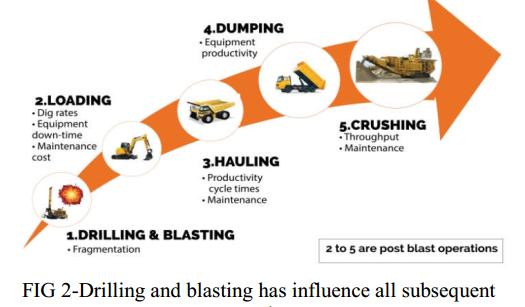

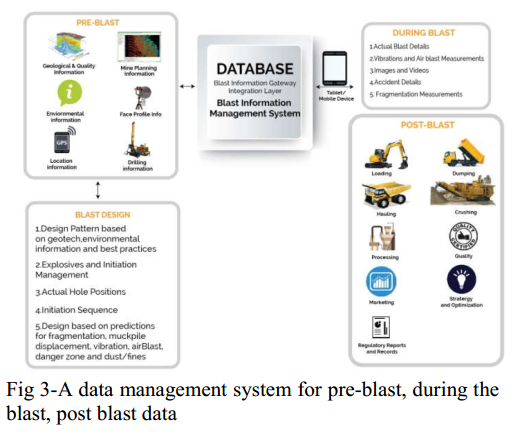

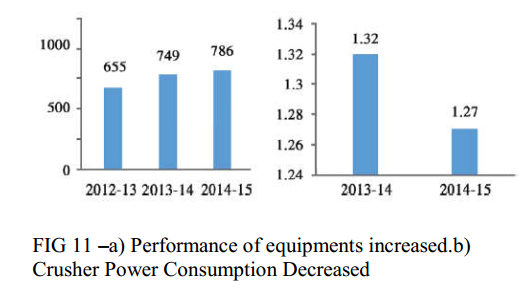

INTRODUCTION mining value chain, from exploration and geological modeling to equipment, operations, maintenance and logistics and transportation.“Consumer” Technologies that is being used every day on our iPhones and Android devices, are providing tremendous opportunity for collecting information and transmitting information. Overlaying the digital world on the physical world and connecting them accurately through intelligent positioning results in additional infrastructure, which is safer and more sustainable use of increased information technology in mining owes its Mining differs from other industries in many ways. It is highly variable, starting with uncertainty about the nature of the resource being mined. Mining operations often take place in extreme environments and in far-flung locations. Strains and stresses placed upon mining equipment by rocks of unpredictable size and hardness result in frequent breakdowns. Smart planning and coordination of activities are required to mitigate variability caused by external forces; disciplined execution is needed to eliminate variability that miners create themselves. The path to a step change in mining productivity will come through reducing and, where possible, eliminating the variability that has made mining unique. Mines using standardized information technology throughout mining life cycle (called as smart or intelligent mine) could help restore the reputation of the industry and align interests of investors, environmentalist and the communities in which mines operate. From blasting to noise to water monitoring, remote monitoring systems can save users operational time and resources by getting data to mining project personnel without requiring them to spend hours in the field. Automatic information gathering, analysis helps mines to save on operating and maintenance costs and extend asset life, while at the same time complying with stringent regulatory and safety requirements. Figure 1 depicts how information from software, sensors, monitors from different sources go to data centre. This analysis provides the ability to be able to do things like streamlining the process, optimizing the operations, as well as enabling people to make informed decisions, People, want to avoid spending a lot of time for finding the right information in order to make decisions, through the technology and the equipment that are used in mining. Lastly, the intelligent mining is seen in the convergence of consumerization and industrialization. The application of “consumer” technologies that we use every day on our iPhones and Mobility allows one to get easy access without having the limitations of network that is available, participate at any geographic location or be involved in, be the project office, or may be on site in front of the assets, or may be with the people at HQ, which has typically been, the place where the information lives. AN EXAMPLE OF DATA MANAGEMENT Blasting is a central activity in mining and quarrying and contributes significantly to overall operations and costs (Figure 2). Fragmentation, an important aspect of blasting result, could affect mucking and crushing performance.However, both could be effected as well by hauling, so that isolated monitoring of mucking could not be sufficient and could lead to faulty conclusions. These considerations lead to overall integrated concept in mining. Thus, it is important that data collections should consider overall concepts in mining. Whereas for other equipment/operations many sensors and monitors purposes, statutory requirements and/or environmental compliance. The review and analysis of past data can improve blast design, execution and help in the achievement of desired blasting outcomes, downstream productivity and process improvement. Based on the database and its search and analysis capabilities, the system can provide opportunities for taking corrective Blasting is made up of groups of tasks, which are performed to produce broken rock with specific fragmentation while ensuring that safety, statutory requirements and/or environmental compliance are met.Being at the very front of succeeding activities such as excavating, hauling, crushing and processing, blasting is also likely to affect the performance of any of these operations (Figure 2). Generally blasting related information is poorly managed with disjointed and unrelated information technology systems managing parts of blasting data. A data management system (Figure 3) not only ensures information storage, but also acts as an intelligent system for optimization of blasting and overall operation. The review and analysis of past data can improve blast design, blast execution and help in the achievement of desired blasting outcomes and downstream productivity, and process improvement. AN EXAMPLE OF DATA MANAGEMENT Blasting is a central activity in mining and quarrying and contributes significantly to overall operations and costs (Figure 2). Fragmentation, an important aspect of blasting result, could affect mucking and crushing performance. However, both could be effected as well by hauling, so that isolated monitoring of mucking could not be sufficient and could lead to faulty conclusions. These considerations lead to overall integrated concept in mining. Thus, it is important that data collections should consider overall concepts in mining. Whereas for other equipment/operations many sensors and monitors automatically send information to data center (Fig 1), details about blasts are not collected as much of it is not automatic. Data collection: pre-blast, during the blast and post-blast is critical to the blasting process, for planning. Based on the database and its search and analysis capabilities, the system can provide opportunities for taking corrective steps by changing explosive charge distribution, initiation timing and sequence for controlling fragmentation size, vibration and flyrock. Data obtained from blast face profiling tool, vibration, flyrock and fragmentation prediction tools, can be directly linked to a database incorporating explosives and accessories used. Modular software may use information to create specific hole by hole explosives loading and create load sheets according to geotechnical zone characteristics and results required. BLAST DATA COLLECTION AND MANAGEMENT SMART BLASTING APP In recent years, there has been growing convergence of ‘consumer’ technologies that we use every day on our iOS and Android devices such as cameras, motion sensors and GPS systems (Akella et al, 2008; McHattie, 2013). The use of mobile devices makes it easier to collect data on-site and it is main stream in many places where a mobile workforce is present. Use of these devices would be ideal in the field for drill and blast personnel. Though mobile devices are not be used within 30 m of a blast, appropriate rugged devices can be used. They would get the required capability of collecting on-site blasting details. As part of the technology solution a mobile app has been developed which works on “Data2Desktop” MINE LINK APP mines within the organ sharing of real time information. A CASE STUDY OF LIMESTONE MINE IN A CASE STUDY OF MINE IN KARNATAKA This mine produces 9.00 Mt/a limestone. The mine was using the drill pattern with a burden of 5.5 m, spacing of 10.0 m and hole depth of 10.0 m (with these parameters as, powder factor 11.60 t/kg, drilling factor 108.79 t/m, cost Rs 3.0 per ton, tonnage per hole as 1375 t). Between 2013 and 2014, the mine was using the pattern with burden of 5.5 m, spacing of 10.0 m and depth of 10.0 m. Analysis of data records of the previous blasts helped and a pattern was gradually changed to a burden of 5.25 m, spacing to 11.0 m and hole depth of 10.0 m. Changes in blast parameters show results in that cost reduced to Rs 2.8/t with powder factor improved to 12.29 t/kg, drilling factor of 111.18 t/m and tonnage per hole increased to 1443 t(per hole getting 68 t more). showed improvement as compared with the previous blast design. FIG 11 performance of equipments increased andcrusher power consumption decreased. This has resulted in reduction of drilling chain and lifecycle of mining and mineral extraction. There is no doubt that the future landscape of mining will be a digital landscape. Companies must invest in tools and analytics that will allow them to become a modern digital mining company. The future will be digital- digital camera, videos, electronic document storage, network data collection, intelligent search software to see trends and optimise operations. The minerals industry is no exceptions, even though it can be slow to accept new technology. Mining industry as we have seen it in the past has been a laggard when it comes to technology adoption. It is time new tools are used tlike Mobile Apps used for data collection and analysis.

In any operating mine, huge data is available in various ways (such as performance condition data from sensors monitoring devices on fixed and mobile assets) through

networks, servers and services. Mines using standardized information technology throughout mining life cycle could help in improving productivity and restore the reputation of the industry by using data analytics from this big amount of data. The information has to be accurate, easily accessible and available fast to the mining personnel. Industry-specific, enterprise-class software

solutions focused on using information technology to support the business processes of mining and make them more efficient and effective. This “big data” can be processed and analyzed to spot trends, help predict events,and formulate reliability strategies as early as the design stage e.g. .reliability-cantered design. The application of information technology is happening at every phase of the

existence to advances in information and communications technology over the past 10 to 15 years that have been truly transformative.

Information from different data sources are in different formats. These software capture, assemble and report data on things as diverse as production, operating hours, delays, machine conditions, water flows, power and conveyors. Three key activities that are enabling information mobility and helping to advance mine engineering are i) information modeling, ii) asset

BHANDARI ETAL 2 Jaipur, India, 20-22 January 2017 MineAdvanTech performance management iii) asset lifecycle information management.

Android devices, such as cameras, motion sensors, and positioning in an industrial context, are producing 3-D experiences. Innovative hand held units allow field data to be captured and automatically down loaded when the unit is docked, eliminating human error during data transfer

automatically send information to data center (Fig 1), details about blasts are not collected as much of it is not automatic. Data collection: pre-blast, during the blast and

post-blast is critical to the blasting process, for planning.

steps by changing charge distribution, initiation timing and sequence for controlling fragmentation size, muck pile displacement, fly rock, ground and air vibrations.

Blast Information Management System (BIMS) software provides information to meet the strategic and operational needs for planning, controlling and decision making for optimizing mining operations (Bhandari and Bhandari, 2006). BIMS provides methods to store, manage, document and retrieve drill and blast related information. The system stores blast details, actual blast parameters,blast pattern, face profile, explosive consumption, charging details, recorded videos be used for observing face movement and hole by hole behaviour. The stored blast information data can be retrieved quickly and easily. Performance and cost of blasts can be monitored and appropriate blast designs for particular areas or different zones can be identified. The data

management and retrieval is easy and simple to use which can be carried out in a few minutes instead of days for manual methods which helps in optimizing various operations. Readily available past data in a logical format and blasting data analysis tools are the key features of the database. Details of explosive charge distribution and initiation used for the holes are duly recorded. The database can be extended to integrate with other systems such as ERP, CMMS etc. If the software is operated in conjunction with a comprehensive monitoring program, it

can contribute to the efficient running of an operation and reduce environmental effects to a minimum. Importing data using .csv file, Excel and other popular mining

software makes it is possible to reduce input work. Entered data can be edited through edit parameters. Integration with other software such as that used for

vibration monitoring and analysis, fragmentation analysis etc. can be carried out so as to provide simplified management system. This tool provides a way of trapping the experience of drilling and blasting personnel to better control critical parameters such as dilution, vibration, fragmentation, and flyrock and fines generation. This database has also

searching options using which the user can look for the records of blasts as per his defined criteria such as blasts between dates, by performance of explosives or initiating system, by vibration limits, by fragmentation size, by location of blasting zone or accident etc.

Presentation of analysis of data, compliance reports suitable for regulatory bodies, archiving and viewing of.

concept (Fig 4) Data2Desktop is an end-to- end technology framework for collecting data at bench face and to monitor remote data points and transfer data to desktop software for prediction and control of impacts. Data2Desktop can also use most communications means including mobile phone and satellite networks to send data from remote locations to the Data2Desktop cloud

based servers. To use this application, mining personnel can take the device to a blasting site. Then drilling and blasting data is entered (as per design) preblast. Once the blasting

is done, actual data is recorded to save it for future use. All parameters related to drilled holes and explosive charging, stemming, etc can be collected. At this stage, the blaster can recheck predicted fragment size distribution, flyrock distance, ground and air vibration, fragment size, etc, and if there is variation from the designed blast and limits are exceeded, changes in

charging, stemming, initiation devices and timing can be done before executing the blast. Photographs and videos can also be saved using the device. Data can be imported from other devices or tools such as vibration monitoring record When mining personnel return from site, they can sync this data to the web version of the application and export it to the desktop because local storage of mobile devices cannot save large amounts of data.

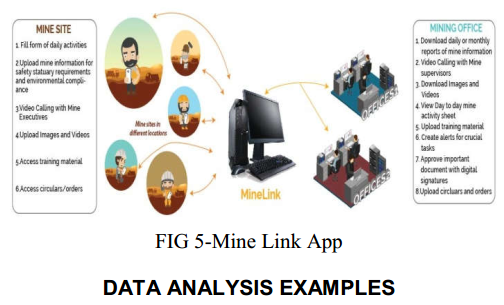

Mine Link Solution is an end-toframework packaged as a simple data service to monitor remote data points. A mining company has a n mines and in each mine there are large numbers of

operations spread over a large geographic area where mining operations are carried out. This requires the application of a new creed of technologies that are capable of monitoring remote mine areas time information and sending it directly to those in the organization that require it, all in real time. All of these challenges mandate a new way of doing things. Fortunately we are living in a connected world. Communications is becoming ubiquitous. Thus a MineLinkApp is a solution which allow users to fill real time information about day to day mine activities, capture images and videos at mine and take video calls at mine itself and concerned person in the organization can download the uploaded data as reports, download images

and videos and take video calls with mine supervisors. Alerts can also be set to enable the reminder for important activities like renewing mine lease etc. This App helps in linking different

NORTHERN RAJASTHAN

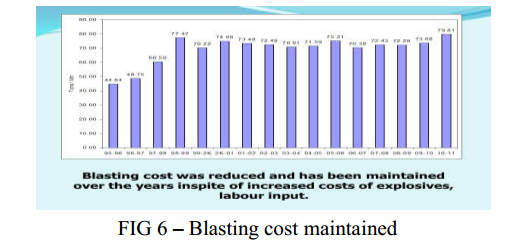

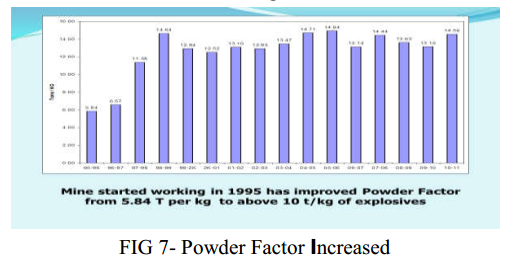

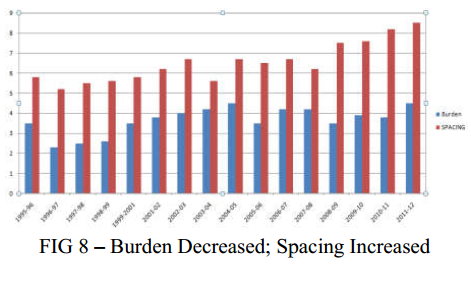

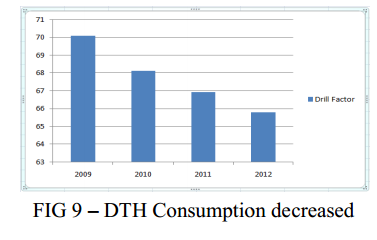

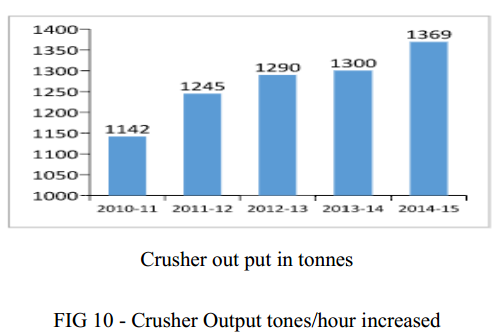

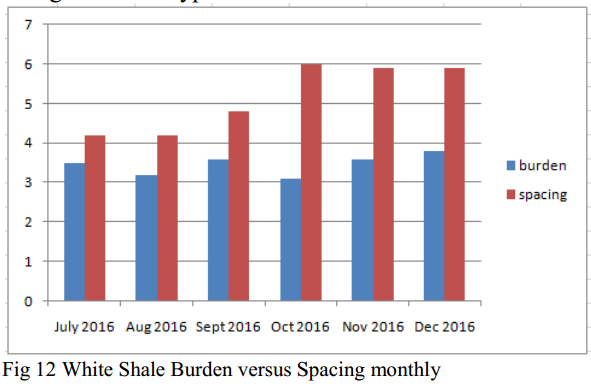

This limestone mine in northern Rajasthan designed to product limestone 6.6Mt/a. The ore to over burden ration was 1:0.33 therefore total rock handling was around 9Mt/a. This mine has been able to store blast related data from the beginning of the limestone open pit mine in 1965 until the present day. This has helped the mine in decreasing the drill factor from 45 t/m to 75 t/m (FIG 6) and powder factor increased tons/kg to more than 14 tons/kg (FIG 7) reduced and spacing was increased (FIG 8) which lead to less holes per blast (FIG 9)thus reducing costs by 50 per cent (FIG 10) while improving crusher t/h to 1369 t/h (FIG 11).

costs and improved powder factor.

CONCLUSIONS:

The use of new technologies in the connected world is inevitable, as it provides the best in class means today of communicating with thousands of points securely and cost effectively. Information and communications technology can be applied to the entire value.